The mining industry is under growing pressure to improve efficiency as ore grades decline, reserves become more dispersed, and costs rise. Artificial Intelligence (AI), cloud computing, and IoT are just some of the innovative technologies that can help increase on-site efficiency, productivity, and safety. Examples include automated drilling, self-driving trucks, and preventative maintenance. By leveraging advanced technology and connectivity solutions, such as 5G devices, sensors, and software installed on vehicles and hardware, mining companies can achieve real-time monitoring and better control of the mining process.

Additionally, connected devices, such as wearable technology and proximity detectors, can augment health and safety measures in mining operations while also providing data on equipment status, potential safety hazards, and current environmental factors. Additionally, IoT technologies are enabling mining companies to automate workflows and improve efficiency, cutting costs.

IoT technology also contributes to more sustainable mining practices, by monitoring equipment and managing environmental conditions at mine sites, including air pollutants, equipment operating efficiency and wastewater emissions, as well as worker safety. By using data from mining equipment to improve efficiency, mining companies can reduce their emissions and improve their ESG credentials.

This trend towards more connectivity is likely to continue as AI and computing technologies progress. However, while IoT brings many benefits to the mining industry, it also poses challenges and adoption of IoT in mining is not yet fully developed. Moreover, increased connectivity of mining operations requires robust cybersecurity measures that companies must invest in to protect new tech operations.

Current market and emerging technologies

Mining has experienced significant changes in recent years, and the industry has become more globalised but, at the same time, susceptible to market volatility. Recently, the mining sector has felt the impact of the Covid-19 pandemic, exacerbating supply chain disruptions and labour shortages. Further, increasing resource depletion means extraction of lower-grade deposits and investing in more advanced and expensive exploration and extraction techniques.

Alongside these changes, technologies such as IoT have emerged and been integrated into the industry, influencing productivity, remote monitoring, automation, predictive maintenance, operational efficiency, sustainability, and workforce safety.

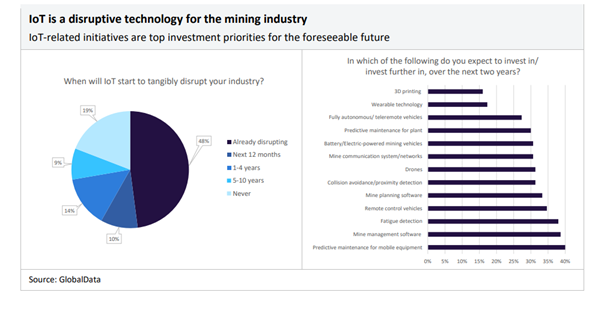

GlobalData’s Tech Sentiment Polls Q2 2023 found that IoT is a prominent theme across all sectors, with 48% of respondents saying that IoT was already disrupting their industry. IoT technology is deployed across the whole mining value chain, from prospecting to reclamation. Its spread has been encouraged by reduced latency, increased computing power, and the falling price of sensors, which have led to a faster ROI.

Additionally, AI has increased relevance across all IoT layers, and a growing number of products and services are now incorporating this technology into their capabilities, especially for predictive maintenance and digital twin modelling.

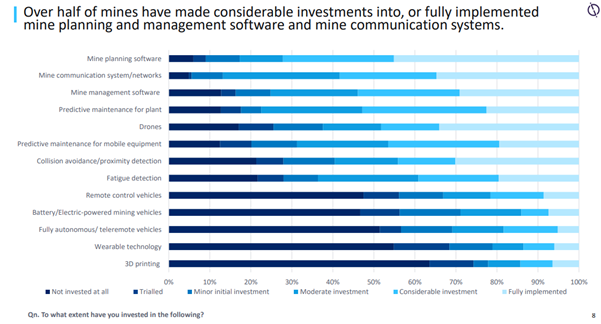

GlobalData’s Global Mine-Site Technology Adoption Survey (2023) reveals that over half of the mines surveyed had already made considerable investments into or fully implemented mine planning and management software and mine communication systems. However, only 19% of respondents have fully implemented predictive maintenance for mobile equipment, and only 23% had fully implemented predictive maintenance for plants.

According to GlobalData forecasts, the total IoT market in mining will be worth $7.8 billion in 2027, having grown at a compound annual growth rate (CAGR) of 16.1% from $3.7 billion in 2022. Moreover, GlobalData’s mine-site technology adoption survey revealed that the investment areas the industry will prioritise in the next two years are IoT-related initiatives, like fatigue detection, drones, and predictive maintenance technology. This shows how focused mining companies are in deploying this technology to digitally transform mining operations.

How technology is changing mining

The increase in technological capabilities has led to a notable shift in the connectivity layer of mining and its evolution across IoT devices, services, and applications.

Chen Wenfeng is Chief Marketing Officer of Huawei Mining Business Unit, and part of a dedicated team at Huawei, ready to deploy technologies designed to enhance mining efficiency and improve working conditions for miners.

“Mining isn’t easy because the environment is very hazardous,” Chen says. “So we considered how we could use 5G communication technology to help. In China alone there are more than two million mine workers, mostly working shifts, with some working to a depth of 1000 metres. It’s also very hot and uncomfortable.

“But what if they could work remotely? Workers can live away from the site and work in a remote office or operations room. Then you can remotely control machinery. We have already realised part of this dream. Over the last three years we have deployed 5G to more than 500 mines in China and overseas, including two coal mines in South Africa.”

Chen comments that using IoT technology also helps with the labour shortage, encouraging young people to choose mining as a career. The latest tech is shifting the industry away from the old stereotype of being dirty and dangerous, and now university graduates with IT and computer backgrounds are interested in a career in mining.

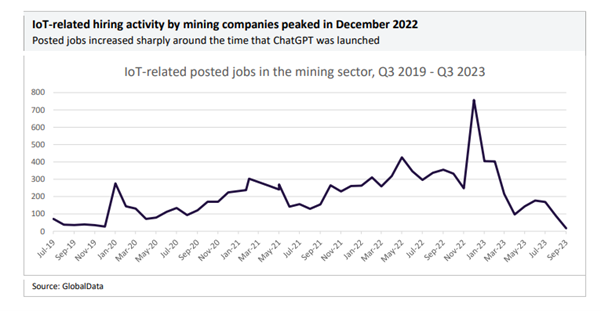

Research from GlobalData’s Job Analytics confirms this with an upward trend in job postings related to IoT over the last few years. As IoT and AI are often complementary, this growth in IoT hiring could be linked to increased interest in AI following the launch of AI services such as ChatGPT in November 2022. While IoT technology gathers sensor data, AI algorithms analyse this data to enhance the automation process, making mining processes more efficient.

Such innovative technology is also helping to reduce operating emissions and help with ESG targets. Using AI technology can improve the efficiency of the whole mining industry, reducing waste and costs from downtime. Chen adds that the development of ‘intelligent mining’ is crucial for achieving net-zero carbon emissions goals in the global major economies.

Eliminating pain points with innovative technology

For Huawei, the essence of intelligent mining lies in the industrial internet. Here, building unified standards and architecture is key, and to achieve this, Huawei follows a Platform + AI + Ecosystem strategy, deploying next generation Information and Communications Technology (ICT) — from cloud computing and big data to 5G, AI, and the Industrial Internet of Things (IIoT)— to construct the mining industrial internet and switch on intelligence.

This allows Huawei to deliver solutions to some of the industry’s main pain points, including difficult working conditions, labour shortages, safety hazards, high operating costs, and unscheduled downtime brought on by maintenance issues.

On-site, the working environment at a mine can be harsh, especially underground, with high levels of dust and noise, and extremes of temperature.

A common cause of accidents occurs due to fatigue caused by driving in a complex mining environment. However, using IoT, 5G and HD video solutions to monitor both machinery and workers, such accidents can be greatly reduced. Additionally, for fully mechanised faces, even in areas 100 metres underground, Huawei’s 5.5G ultra-large uplink capability, with over 100 HD cameras, can be deployed for real-time video uploading. Using AI technology to stitch together panoramic videos, this 5.5G smart solution enables a ‘see all, see clearly’ viewpoint for underground operations, significantly contributing to safety.

Improving the working environment of miners improves working efficiency and reduces operators’ workload – avoiding fatigue driving and reducing accidents. Additionally, mobile and wearable sensors can constantly monitor the working environment, including air quality and temperature. Such remote working solutions and the increasing use of IoT and AI have seen an increase in interest in working in the industry, encouraging graduates to take up positions within the sector, previously viewed as undesirable and ‘old-fashioned’.

The use of AI, alongside IoT, allows analysis of every process, including production capacity targets, security violations, and decision-making. Digital asset management ensures zero idle assets and stocktaking in seconds, via Wi-Fi 6 all-in-one AP with Wi-Fi, RFID, and Bluetooth. Monitoring of energy efficiency cuts costs while also reducing on-site production emissions.

Finally, preventative maintenance, using sensors to monitor equipment and identify and correct problems immediately, reduces downtime by managing maintenance more effectively.

Huawei is using the latest technologies to provide solutions

However, for intelligent mining to work effectively, many different types of equipment need to talk to each other, in a consistent and efficient manner. But most types of commercial mining equipment will use different interface standards.

This is where Huawei’s MineHarmony OS comes in. MineHarmony is an operating system designed to unify data standards in intelligent mining, enabling equipment to communicate with each other, using sensing technology to ensure consistent data protocols and connections between different systems.

Chen explains that this OS is key to the intelligent mine:

“MineHarmony OS is dedicated to IoT systems. For instance, there could be more than 20 operating systems in the different machines [in the mine] and because different machines use a different OS, then their inter-communication is poor. With MineHarmony installed, the data format and the protocols all speak the same language, the same data format.”

For example, a coal shearer usually uses three operating systems, three communications protocols, and 161 kinds of chips. MineHarmony ensures consistent data protocols and formats, simplifying connections between the different types of equipment and making intelligent collaboration possible.

MineHarmony also supports the upgrade of sensors, equipment, and portable devices, and supports smooth data transmission to the cloud through integrated mining bearer networks using 5G, F5G, and Wi-Fi 6 technologies. The OS also realises cross-system data interconnection, which is key to intelligent system development and application replication in batches, laying a solid digital foundation for intelligent mines.

To learn more about how Huawei’s solutions can make mining safer and more productive, click here