Tokyo Electric & Power Company (TEPCO) completed the Kazunogawa Power Plant in Japan’s Yamnashi Prefecture in 2000. The plant is an 800MW underground pumped storage plant that depends on Sagami River’s water.

The Kazunogawa Plant was first planned in 1995, when demand for power was at peak level. The utility company had to balance the day and night power demand differences as there was a huge increase.

The plant was planned and designed for a capacity of 1,600MW through four 400MW units, but just two units were constructed.

Operations of the first 400MW unit started in December 1999. The second unit started working in June 2000. When completed, the plant was the largest hydro plant in Japan.

TEPCO constructed another storage plant at Kannagawa immediately after completion of the Kazunogawa plant. The Kannagawa plant has an installed capacity of 2,700MW.

Make-up of Kazunogawa hydropower plant

The Kazunogawa plant site lies in the eastern side of the Shimanto strata, which are believed to have formed 65 million years ago.

The plant consists of an underground power station, an upstream dam and a downstream dam. It also includes main / temporary tunnels connecting the dams and the power station.

Related project

Bogong Hydropower Station, Alpine National Park, Victoria, Australia

Bogong Hydropower project, near Bogong Village in the Alpine National Park of Victoria, Australia, is the largest hydroelectric project built in the country in nearly three decades.

The discharge capacity of the plant is 280m³/s, with the dams located 5km upstream and 3km downstream, in a straight line for easy flow of water.

The cavern is approximately halfway between the upper and lower dams, 500m below the earth’s surface. The cavern is 210m long, 54m high and 34m wide, with a volume of 250,000m³ capable of holding three jumbo jets.

Challenges were posed at the construction site because of the ground stress and rock joints. Problems in the bedrock were tracked using 1,300 sensors. A detailed analysis of the site was conducted to study and analyse the bedrock. A 1:5 scaled down site was excavated to collect the samples for analysis. The excavated portion was used as a temporary storage for spoil once the main gallery became operational.

A 714m head is provided between the upper lower reservoirs. The upper reservoir includes an 87m rock fill dam. A headrace tunnel with penstocks connects the upper reservoir to the underground power station.

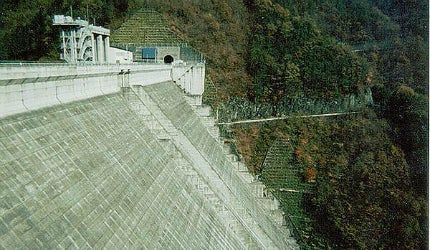

A tailrace tunnel links the power station with the lower reservoir, which includes a 105m concrete gravity dam. The volume of the downstream dam is 620,000m³.

The power station is installed with two Francis turbine generators.

Suppliers involved with the Kazunogawa hydropower plant in Japan

Domestic suppliers were preferred over foreign ones for the Kazunogawa hydropower project.

The main equipment for the plant was supplied by a consortium of Hitachi and Mitsubishi Heavy Industries (MHI).

Furukawa Electric supplied cable and associated extrusion-molted joints (EMJs) and horizontal gas-immersed sealing ends for connecting the plant’s units. The 2,300m long cable was the world’s longest interconnection cable at that time.

Power market in Japan

Vertically integrated general electric utilities dominate the power generating industry in Japan, with Independent Power Producers (IPP) are the largest electricity wholesalers in the country’s power generation market.

Revisions to the Electricity Utilities Industry Law in December 1995 helped IPPs to gain the market.

A 2.1% growth in demand for electricity was expected in Japan every year at that time. International authorities also pressurised Japan to reduce the greenhouse gas emissions, which raised the need to save energy and reduce the power consumption.

Pumped storage schemes formed 8% of all power plants planned or under construction in Japan in 1995.